During my latest kitbashing job, it occurred to me that probably few modellers today have ever heard of C&BT Shops boxcar kits. Back when they first came out in the late 1980s, these were a big deal. After years of nothing but generic ‘Blue-Box’ boxcars from Athearn and MDC, HO-scale modellers were being supplied with affordable, yet good quality models with separate detail parts. We now had kits to build specific prototype models, like the PS-1 from McKean, or the 1950s-era AAR boxcar from Front Range.

The C&BT Shops kit added to the variety by offering the 1944-AAR designed boxcar, an importance predecessor model to the car Front Range produced. This was an even bigger deal for Canadian modellers because the ends of a 1944-AAR boxcar, what hobbyists coined the 4-4 pattern Dreadnaught end, where found on thousands of Canadian-built boxcars well past their usage dates in the USA. These ends were utilized from the late 1940s right until the early 1960s, and helped us Canuck modellers by making it easier to re-create accurate boxcars with minimal effort. Back in the WRMRC’s early years, these were a critical model for us.

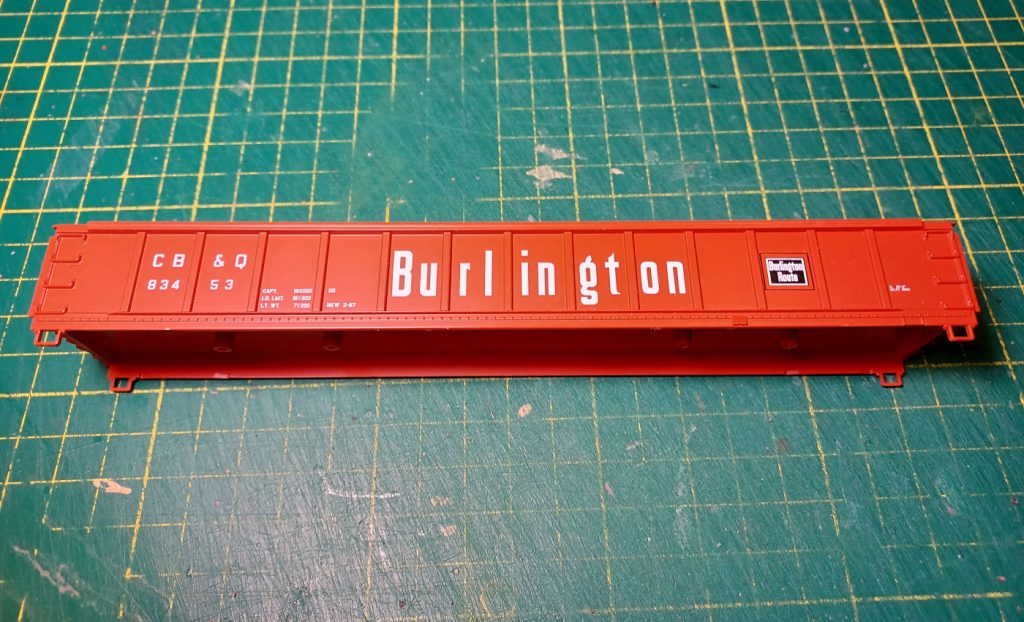

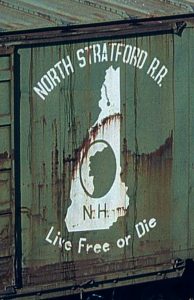

C&BT Shops kit for the 1944-AAR Boxcar with 6ft-door. They also offered a 1949-AAR car, and both kits were available in 6′, 7′, 8′, and double-door versions. Though the main body, doors and underframe are all good quality, the detail parts provided were rather crude and brittle.

There was however a big drawback with the C&BT kit. Though the moulding of the boxcar model itself was very good (they stand up to many models still in production today), the detail parts provided were coarse and of poorer quality. Also the plastic used was brittle, so you’d easily break these parts just cutting them from their sprues. This probably was what ultimately doomed C&BT from becoming a bigger player in the hobby, like Intermountain or Proto 2000 became, even though those manufacturers arrived on the scene later.

Over the decades, I’ve come to learn the history behind C&BT’s troubles. The story was their original tool & die maker had passed away just after finishing the main model, and another person of leaser experience was rushed in to complete the detail parts. Then once on the market, rather than upgrading the parts sprue, they decided to go the Accurail route (who just started up in the early 1990s) by re-engineering the moulds with cast-on details. The company lasted a number of years like this well into the 2000s, but with their momentum gone, they eventually exited the market.

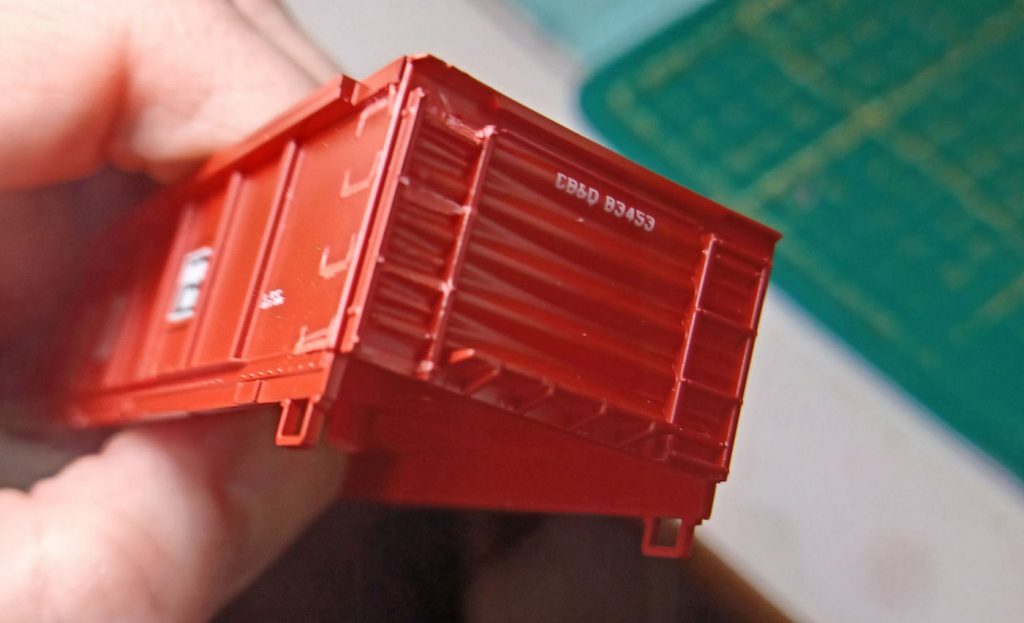

This started off as a later C&BT car with moulded-on detail, and pre-painted in the CPR ‘stepped-Gothic’ scheme. Look close you can still see the original lettering under the primer. All moulded labbers and grabirons were removed, new resin NSC-3 ends added, and miscellaneous details applied. Grabirons will be added later as they will get in the way of Multimark application.

The impetus for this project was a gift of surplus equipment given to the CP Sudbury Division. The donation consisted of several CPR boxcar models from different manufacturers, and included this C&BT blast-from-the-past. It was a later-issued kit with moulded details, and pre-painted in the Canadian Pacific ‘stepped-Gothic’ paint scheme. Additionally the paint was a very bright oxide red, much more like CN oxide than CP tuscan, and also the lettering was too thick. It was however an accurate model for a CPR boxcar featuring; a diagonal panel roof, 4/4 pattern Dreadnaught ends, and appropriately numbered in the CP 258xxx-series. I initially considered salvaging the original paint, but the detail-nut in me could not tolerate the moulded-on details.

‘B’ end details shown here before a primer coat was applied. Ladders and grabirons are Intermountain parts. Brakewheel is Kadee, in an old Front Range (I think) housing. The brake platform was fabricated with re-bent staples and a piece of photo-etched roofwalk material.

The ladders and grabirons were removed and sanded down from the car-sides easily enough, but cutting into the ladders on the car ends was a challenge. I found the plastic much tougher that the polystyrene which Accurail uses, who’s kit’s I’ve hacked and modified many times over the years. So I chose to cut the ends off entirely, as I reasoned that replacement had to be easier than all the hacking, gouging and sanding my original approach would take. That and I’ve collected many different boxcar ends from various old kits over the years. Then as I looked though the collection, I noticed how many stored Sylvan NSC-3 ends were in there (now offered by Yarmouth Model Works). Rather than kitbashing a run-of-the-mill 40ft boxcar that Intermountain and Atlas already offer ready-to-run, why not make it an uncommon car? And heck, if I’m going this far, it deserves a new paint job. My quickie kitbash job soon turned into the dictionary definition of mission creep.

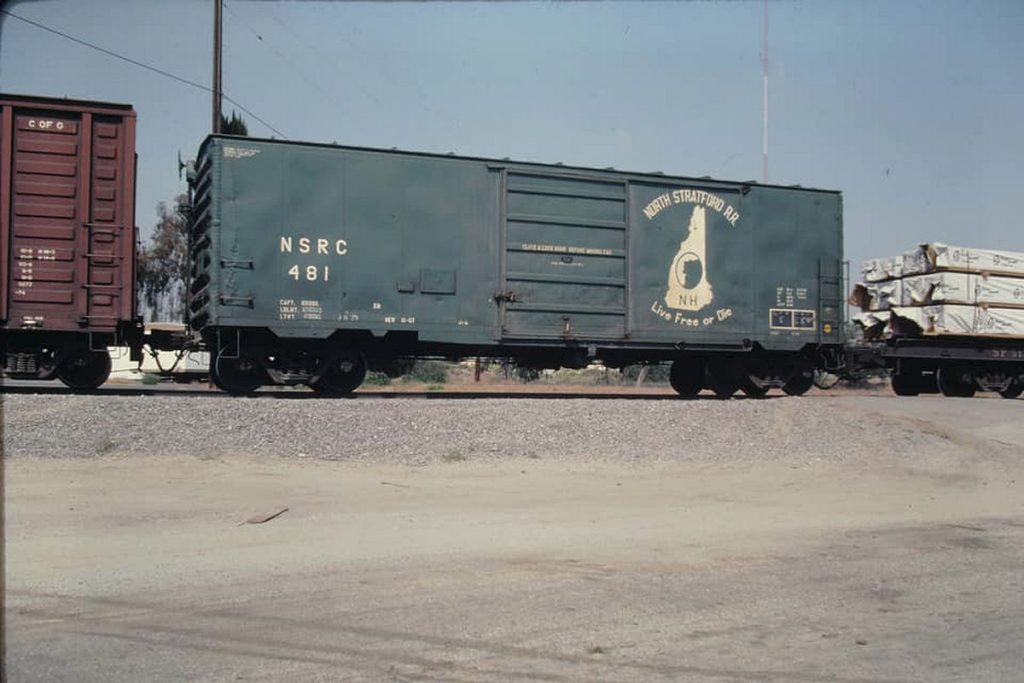

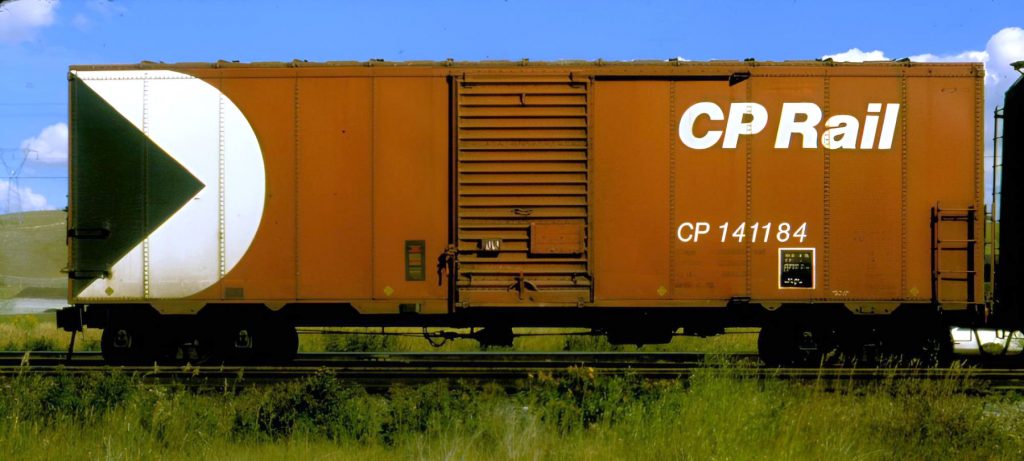

Now that this project had gotten well into the weeds and had become a serious kitbash, I had to choose a prototype to work from. The decision to add an NSC-3 end onto a car equipped with a 6ft Youngstown door and a diagonal panel roof narrowed it down to just one specific order of Canadian Pacific 40ft boxcars; series CP 140950-141699 delivered in 1954 from National Steel Car. Using Chris vanderHeide’s invaluable Canadian Freight Car Gallery website, I found a great photo of CP 141184 within this specific series.

Built in 1954 by National Steel Car, CP 141184 was photographed by Andy J. Broscoe at Bowness, Alberta on 29 August, 1980. Photo courtesy of canadianfreightcargallery.ca

These 1954 built cars were among the last 40 foot boxcars with 6 foot doors received by the CPR, as North American industries began to adopt palatalization and forklifts for logistics and shipping. The following year railways would adopt the 8 foot door as the new standard, and Canadian Pacific was no exception to this.

The CPR received four different orders of 40ft boxcars through 1954, two a piece from Canadian Car & Foundry of Montreal, and two from NSC in Hamilton ON. After receiving literally thousands of near look alike 40-foot boxcars from three different builders within the 250/260xxx series from the late ’40s to early ’50s, these last four orders were each unique. To start, CP was running out of space in the 260xxx’s, and placed these in a new 140xxx-series of road numbers. Next, each one of these orders featured variations in end, roof and door designs; so even the same builder’s two deliveries that year each had visual differences between them. This is another case why prototype modellers should use photographs and reference materials before embarking on any super-detailing projects. This also provides a segway to mention that we have a multi-part series on CP 40ft steel boxcars in the works, so stay tuned.

Since I wished to paint this boxcar in the Action Red 1970s CP Rail scheme, all details were added except the grabirons found on the lower, left-hand sides of the model. The simple reason is they would interfere with the future application of the Mulitmark, and thus are easier to apply after all painting and decal work is complete.

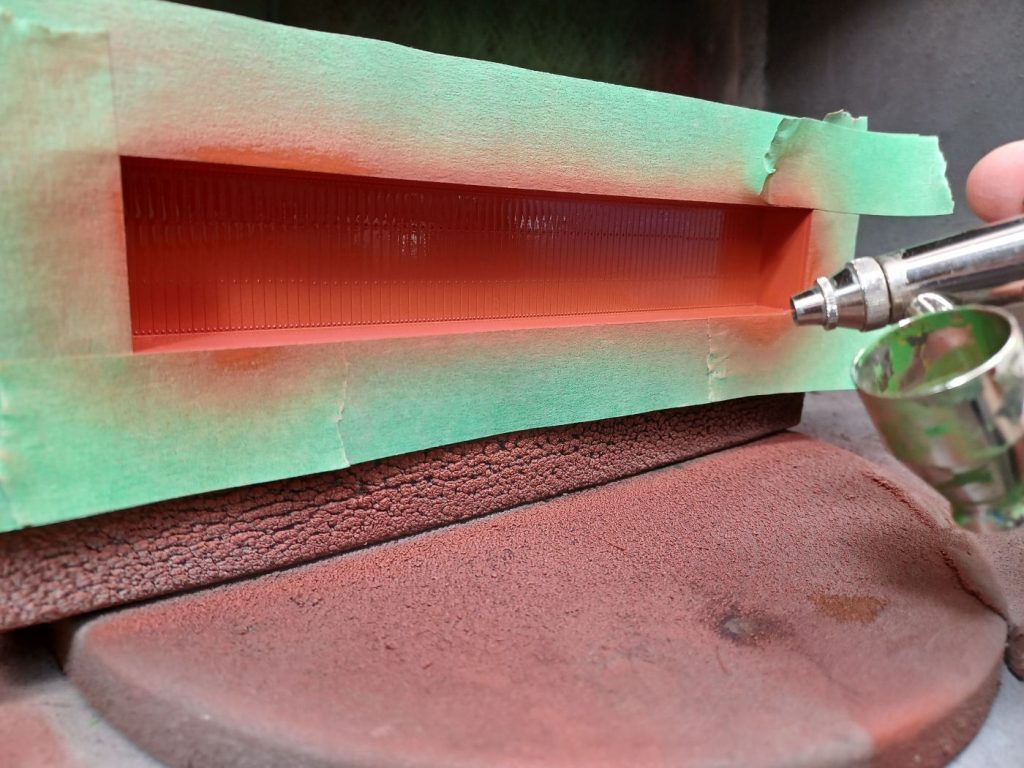

C&BT car at the spraybooth with a fresh coat of Vallejo Air 71085 ‘Ferrari Red’. Click on this image and you can see traces of the old CPR lettering. Normally I remove old graphics before repainting a model, but a barely detectable older scheme showing on a CP Rail boxcar was a real thing.

I am a long-time convert to airbrushing with water-based acrylic paints, and I’m often asked what product I’ve switched to with Polyscale being gone. For a few years I continued to use Testors products, as their ‘Chevy Engine Red’ aqueous acrylic was a close match. But with them leaving the market for good, like most everyone else I’ve switched to Vallejo. After my first few sprays, my initial reaction was Testors who? Vallejo manufactures a superior product. Full stop. The problem of course is they offer no railway specific colours, though that is slowly changing.

For CPR freight equipment tuscan oxide, I find 71039 Hull Red is a good match. Please don’t let the internet fool you, the colour is lighter and more reddish than that image appears, at least from the one displayed on my screen anyhow. For Action Red, I don’t think you will at all be displeased when you spray with 71085 Ferrari Red. To my eyes, it is an almost exact match to the old Accupaint Action Red, which I’ve always considered was the closest thing to the real deal. The daylight LED lighting at our club may affect photography, but the image below is straight from my phone. To my eyes, that’s the orange-red appearance typical of good old CP Rail Action Red.

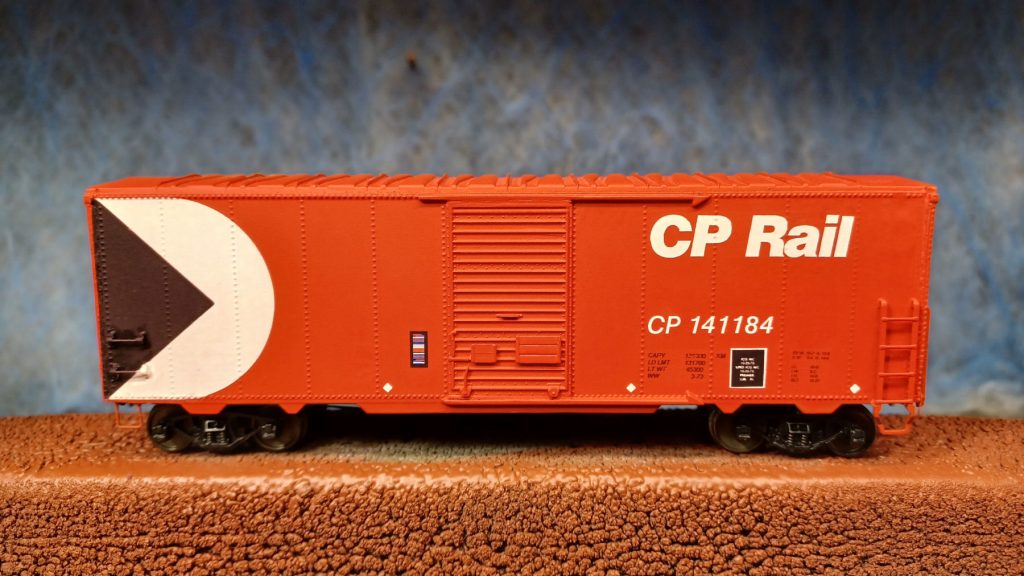

CP 141184 after all decals and grabirons were applied. There is a colour mismatch after brush painting the grabirons to match the Multimark, but that will all disappear after final weathering.

For decals, the CP Rail herald, road numbers, ACI lable and COTS plate are all Microscale products. The black dimensional data lettering is a personal set I printed using inkjet decal paper. The Multimark, diamond-shaped reflector stickers, and end lettering were from a old used Herald King boxcar set. Yes, I pieced together the tiny road numbers decal by decal on the ends. No, it wasn’t fun.

For weathering, I applied some Pan Pastels ‘raw umber’ along the rivet seams, doors, and roof panels. This would be a 1970s repaint, so it should be lightly weathered for the club’s modelling era. Some dark soot weathering powder was used around the ladder rungs and grabirons, to simulate the grimy gloves and boots of the employees climbing around the equipment. Then a very light coat of Mission Models Rail Tie Brown was sprayed along the bottoms of the model, to simulate dust and dirt kicked up from the tracks. The whole thing was then sealed with a flat coat to protect the decals and weathering.

When you look at this final photo of the finished car, you see it compares well to many current production models on the market. Not bad for a 1980’s tooled product. So if you’re at a train show or flea market and spot a grey and maroon C&BT box, maybe stop and take a look inside. If you’re lucky and find an early production model, don’t let the detail parts discourage you. Chances are it’s selling for cheap, and all the replacement details you need are available from Tichy Trains and others. If you still decide against it, as least you know the story behind the C&BT Shops boxcar.